The 3-D printing process is truly the most advanced technology for realizing components quickly! When requiring multiples and parts in other colours and materials, the Scott AM Vacuum Casting Process can help enormously to produce any number of parts, in any colour and in any type of material. Scott AM offers 14 materials, certified: UL94 VO and Material with FDA requirements and all RAL colours.

Scott AM Vacuum Casting Machines are unique and can be utilised for at least 6 different applications

SCOTT AM 1000 Series

From prototypes through to low volume production, Scott AM vacuum casting systems are proven solutions – high quality, repeatable, cost effective components in a wide range of materials.

Featuring:

- Automatic mixing and pouring operation

- Programmable PLC control and automation to ensure consistent quality

- Touch-screen control panel

- Simple to navigate menu system

- Small system footprint – ideal for small workshops

- Vario-Vac™ for casting high viscosity resins

- Heated cup option

With the capability to cast:

- Polyurethane resins

- Nylon PA6 and glass or fibre filled polymer – using the Nylon Plus option

- Wax for investment casting masters and low melt alloys

- with the heated cup option

- TCV - differential pressure system for casting high viscosity resins

System specification

- Dimensions without accessories (H x W x D):

1200 mm × 900 mm × 600 mm (47.2 in × 35.4 in × 23.6 in) - Maximum recommended mould size (H x W x D):

480 mm × 440 mm × 420 mm (18.9 in × 17.3 in × 16.5 in) - Casting capacity: 1.0 L (48.8 cu/în)

- Power supply: 230 V, 50 Hz (other power supply configurations are available)

- Pump capacity: 25 m³/hr (883 cu/ft/hr)

- Ultimate vacuum: 0.5 mbar (7.25 psi)

- Net machine weight: 267 kg (589 lb)

Machine specification

- PLC control and automation – to ensure consistent casting

- TCV - differential pressure system for casting high viscosity resins

- Heated cup – suitable for casting high quality wax masters and low melt alloy

- Maintenance packages

- Training programmes – tailored to suit your requirements

- Consumables – including PU resins and silicone rubbers

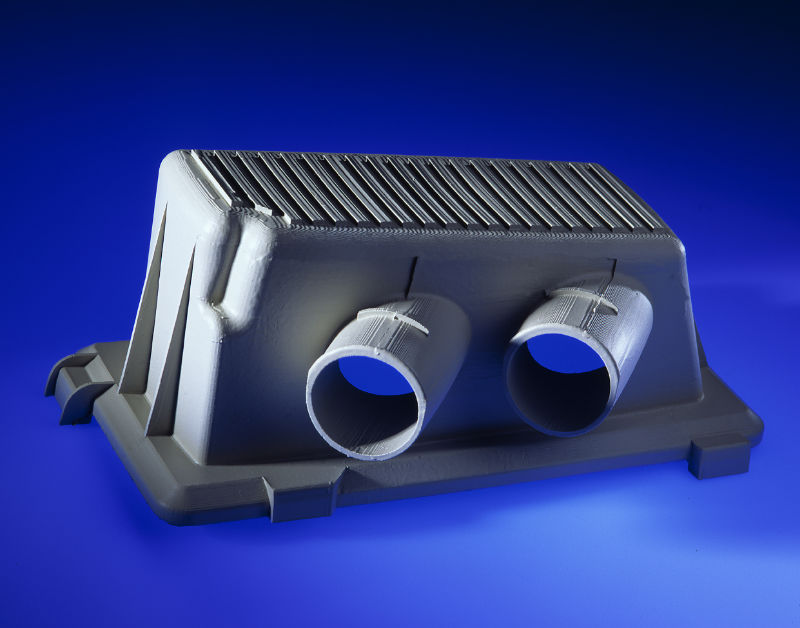

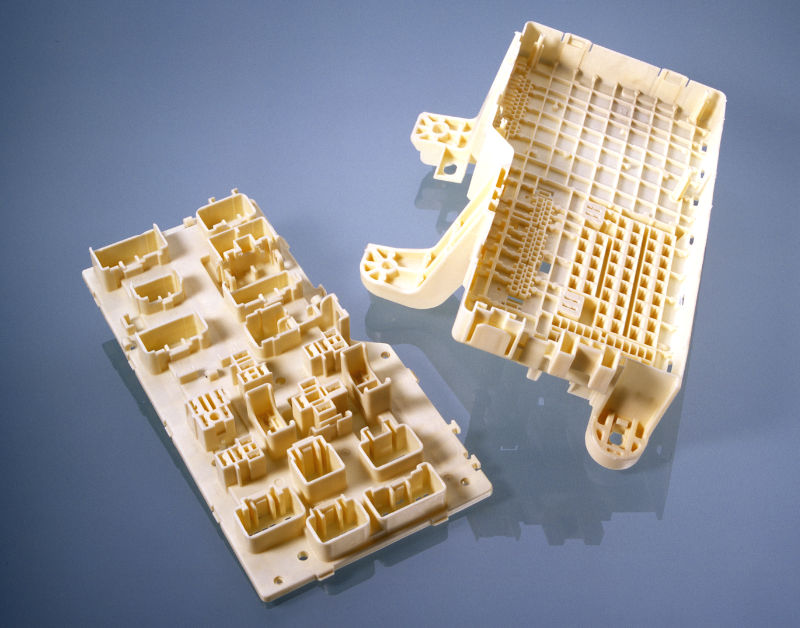

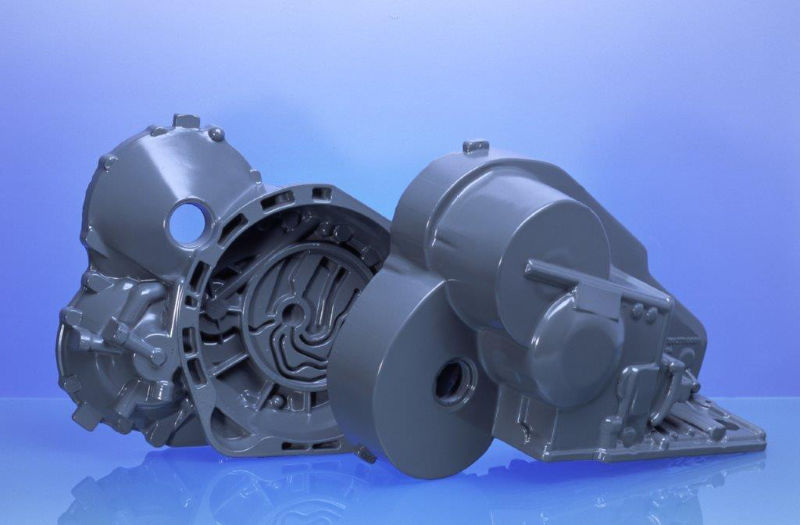

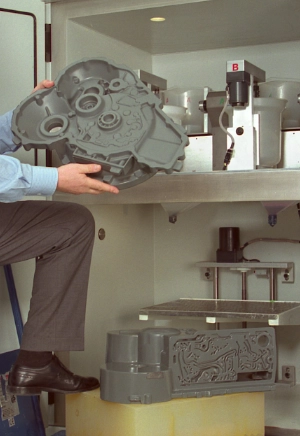

Typical parts produced with the Scott AM 1000 vacuum casting machine

SCOTT AM 4000 Series

From prototypes through to low volume production, Scott AM vacuum casting systems are proven solutions – high quality, repeatable, cost effective components in a wide range of materials.

Featuring:

- Fully automatic or manual operation

- PLC control

- Touch-screen control panel

- Simple to navigate menu system

- Small system footprint

With the capability to cast:

- Polyurethane resins

- Nylon PA6 and glass or fibre filled polymer – using the Nylon Plus option

- Wax for investment casting masters and low melt alloys

- with the heated cup option

- TCV - differential pressure system for casting high viscosity resins

System specification

- Dimensions without accessories (H x W x D):

1930 mm × 1510 mm × 900 mm - Maximum recommended mould size (H x W x D):

750 mm 900 mm × 750 mm (29.5 in × 35.4 in × 29.5 in) - Casting capacity: 2.2 and 5 Ltr

- Power supply: 3 phase 400 V 3NPE, 50 Hz, 3.5 kW

- Pump capacity: 65 m³/hr (2295.5 cu/ft)

- Ultimate vacuum: 0.5 mbar (7.25 psi)

- Net machine weight: 1150 kg (2535 lb)

Machine specification

- PLC control and automation – to ensure consistent casting

- TCV - differential pressure system for casting high viscosity resins

- Heated cup – suitable for casting high quality wax masters and low melt alloy

- Extension chamber – for projects larger than the capacity of the standard system

- Maintenance packages

- Training programmes – tailored to suit your requirements

- Consumables – including PU resins and silicone rubbers

Typical parts produced with the Scott AM 4000 vacuum casting machine

The Answer to High-Viscocity Mixing

The Scott AM Mixer is a new technical innovation which both mixes and de-aerates silicone mould and resin materials for the Scott AM Vacuum Casting Process. The Silicomat frees the Vacuum Casting Machine to do it's primary function – casting and producing prototype components.

The Mixer is specifically designed to mix and de-aerate and is more than a combination of hand mixing and then de-aerating in the vacuuum casting chamber.

Some important advantages of the Mixer are:

- three times quicker than with usual, traditional methods

- no idle time for the Vacuum Casting Machine

- no manual mixing

- thorough mixing of both silicone and catalyst

- mixes large quantities of silicone quicker

- user friendly controls

- less wast, mixes silicone in original containers

- completely portable unit

- NEW: Degasing and mixing of Scott AM EP Tooling Resin

Scott AM MIXER PLC

- Dimension Housing (HxWxD): 1090 mm x 550 mm x 900 mm

- Weight: 140 kg

- Volt Hz: 550 / 240 V, 50Hz

- PH: 1

- Amps: 11

- Torque: 84 nm

- Max Drum Size *: DIA 315 x 410

- Control System: PLC with Touch Pad Screen

- Standard Drum Size: DIA 300 x 360

- Speed at 50 Hz: 26.31

![]() the Full Service Supplier offers the widest range of machines, mould making and casting materials, tools and accessories, complete customer training - worldwide. Scott AM Tooling and Casting Technologies guarantee by far the quickest return on investment.

the Full Service Supplier offers the widest range of machines, mould making and casting materials, tools and accessories, complete customer training - worldwide. Scott AM Tooling and Casting Technologies guarantee by far the quickest return on investment.